New LNG Receiving Terminal, Rayong

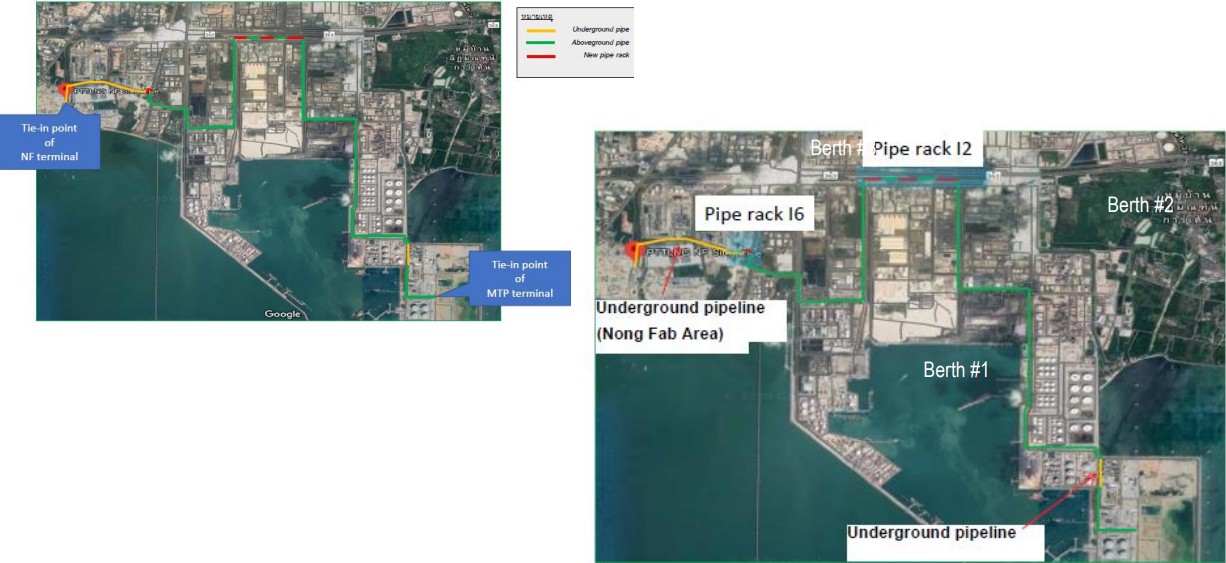

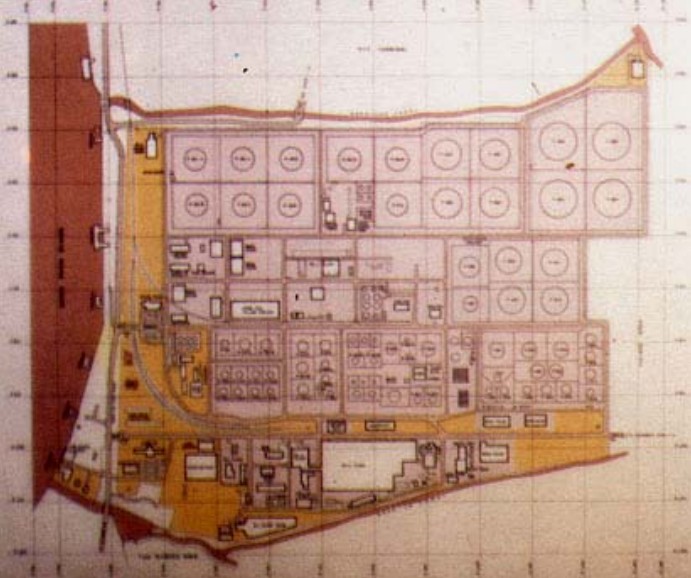

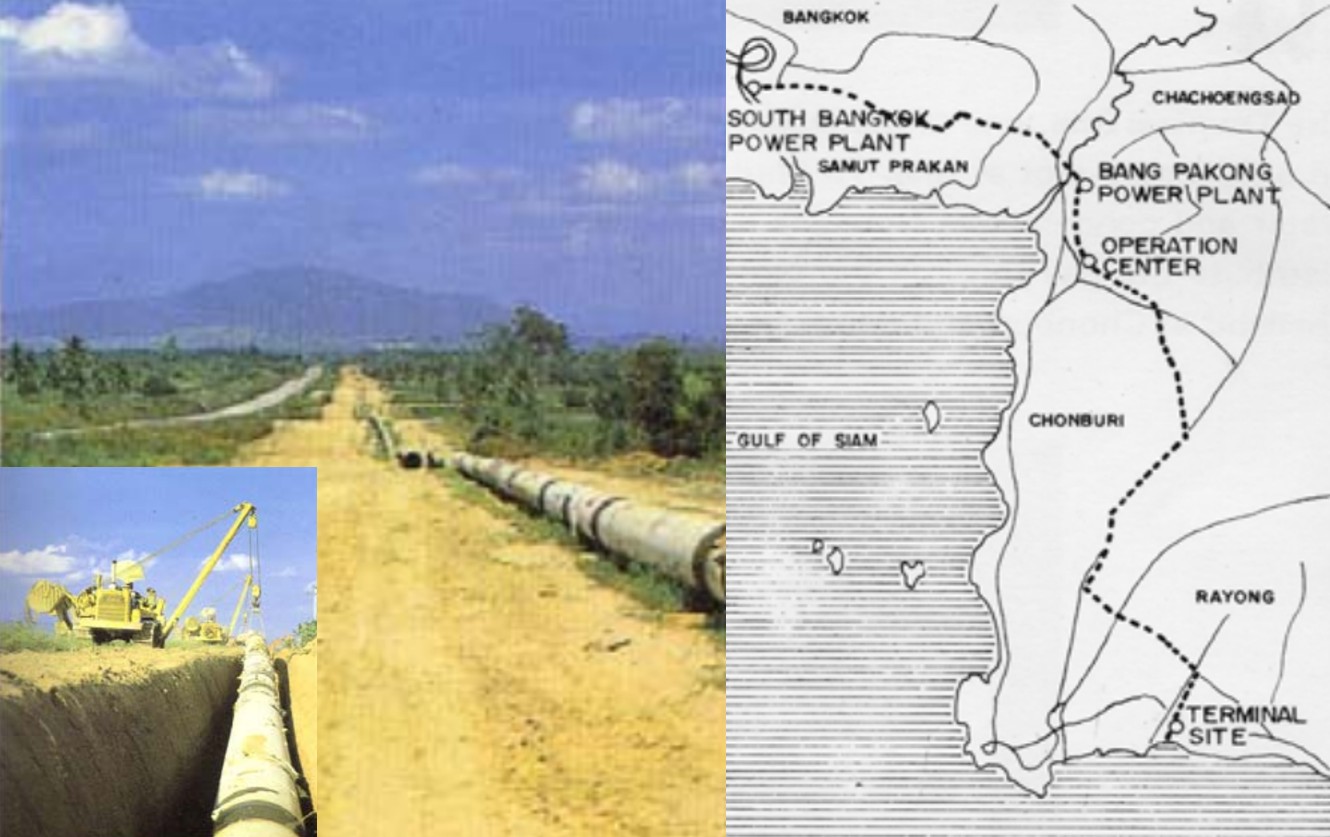

This project involved the tender and detailed design, as well as construction engineering services, for the marine structures of a new LNG Receiving Terminal in Baan Nong Fab, Rayong, for PTTLNG Company Limited. Valued at 38,500 Million Baht, with the consultant's contract at 12.026 Million Baht, the project ran from December 2018 to May 2021 (2561-2564 in the Thai calendar). The NSC Consortium (NSC and SPAN) was responsible for the marine civil works.

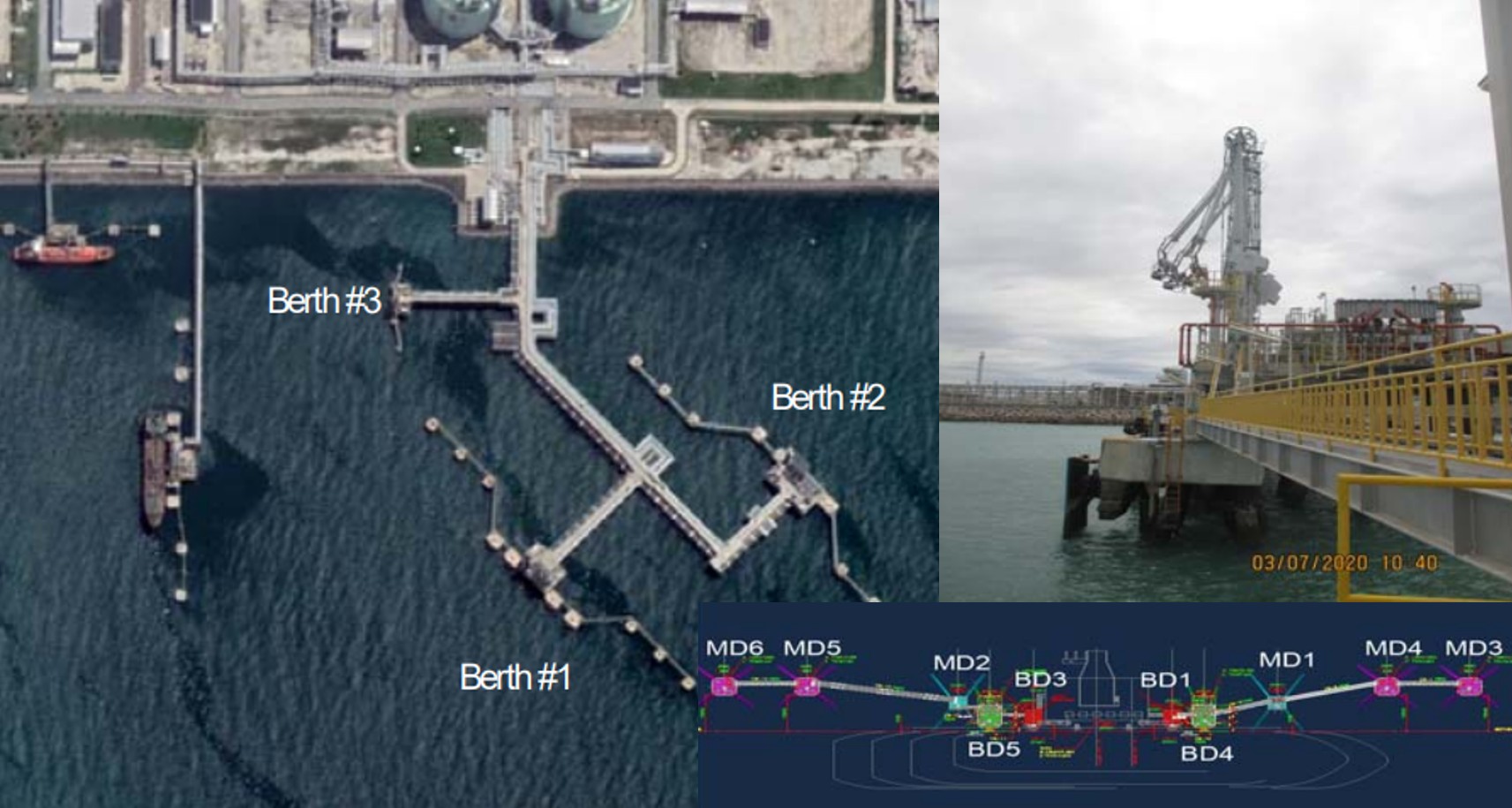

The core of the marine infrastructure included an approximately 5-kilometer-long approach jetty trestle, featuring a 24-meter typical span length and a 5-meter-wide roadway. This trestle, supported by 1.60-meter-deep precast prestressed concrete I-girders, connects the onshore LNG receiving terminal to the jetty head. At the jetty head, two berth structures were designed, complete with essential berthing facilities such as unloading arms, a gangway tower, and mooring and breasting dolphins. A separate platform houses the Jetty control room, overseeing all structures in the berth platform area. Additionally, tie-in structures were included to connect LNG main pipes from Berth #2 to the onshore terminal, bridging operations until Phase II commences.

The project also encompassed the design of both onshore and offshore seawater intake and outfall structures. These facilities utilize double concrete tunnels (3.20 meters in diameter, 1350 meters long) constructed via the pipe-jacking method for intake. After processing at the terminal plants, the seawater is discharged back into the sea through another set of double concrete tunnels (3.20 meters in diameter, 1150 meters long) and a 400-meter-long steel diffuser pipe. Furthermore, the project included the design of a reinforced concrete retaining wall, measuring 7.75 meters in height and 575 meters in total length.